Maybe the fibers that once defined the world change the world again.

When you say "knitting", you may have the image of a diagram that a grandmother moves with a thick knitting needle, or something like a winter hut like a snowy hut.However, in fact, knit products are not only for sweaters and mufflers, but also every year, and can be said to be most common in socks to T -shirts, sweatshirts, knit hats, etc. directly.

And now it's been several thousands of years since the skill of knitting was braided, and new knit technology has been born, and we are trying to change our basic clothing from the ground up.As a result, our bodies are becoming more and more connected to modern computerized worlds.

Most clothes are formed by cutting the fabric and sewing them in T -shirts and sweatshirts.But, for example, UNIQLO sells a dress with a special knitting machine for less than 3000 yen, rather than cutting and connecting the dough.

This technology called "hole garment" or "no sewing" was developed by Japan Island Seiki Manufacturing, but it was not a mainstream until recently due to its high cost.The mechanism of this knitting machine is like a 3D printer's clothes version, and when you put a thread and program the machine, clothes come out from there.

This technology has made knit shoes, adidas WAP KNIT leggings, and NIKE's Pro Elite Knit shirts.Some believe that it has played a part of the recent "Asler" boom.Combined with the innovation of the related fields, such as the fibers that are the material of the knit, the hole gurment leads to further applications in the future.For example, a coat that can adjust the cold protection as needed, or a shirt that can measure your heart rate.

The major difference between the future clothes and the existing (a little disappointing) wearable device is whether they are integrated with ordinary clothes and seamless.Future smart clothes should hardly be distinguished from the usual clothes without batteries to operate it.

History of knit technology

We don't usually connect plain white T -shirts and technology.But T -shirts sold at that supermarket are engineering tads of "destructive creation" that human beings have crossed over and over again in thousands of years.

It is thought that there was a textile in front of the knitting, but the oldest surviving clothes are the Egyptian knit socks.It was made with an early knitting method called "Narberthrain", and there was only one knitting needle.

Until then, humans would have worn only like sandals or fabric bags.For the first time, imagine the feeling when the sweat and octopus -filled feet slide into the soft knitted socks.That is exactly the destructive creation that the knit first caused.

During the industrial revolution, the times went down, and knitting and weaving machines were mechanized more and more.The first automatic loom, born in the early 1800s, was a pioneer in modern computers using binary code, triggered the Raddy Movement against mechanization.In the era when rural scenery was spreading in Silicon Valley, the textile industry was shaping the world, and fibers were wealthy, exploited, and caused wars and revolutions.

It may not be so noticeable now, but fiber technology may be a cutting -edge technology again in the near future.Many designers dream the possibility of a fabric with smart functions.

The future is soft

I asked REBECCAH PAILES-FRIEDMAN, founder of Interwoven Design Studio why knit is noticeable as a smart fabric.Her answer is simple, "Most of the clothes that everyone has now is knit."

According to Despina Papadopouros, the founder of Principled Design, has a feature that is suitable for smart use.PRINCIPLED DESIGN collaborated with Ralph Lauren at the 2018 Winter Olympics and developed a jacket with a heater function.Papadopoulos says that modern knit technology is an increase in control to shape, especially when fusion with conductive threads.

"In terms of three -dimensional, it is easier to control than fabrics," said Papadopoulos."With excellent three -dimensional properties, it is easy to operate the structure of the fabric, but can also create pockets and create a layer structure that can seamlessly incorporate electronic devices. This is not possible with other technologies.is".

It may be difficult to understand what is good in seamless.However, looking back on the failure of a wearable device that is not like Google Glass, you will see the difficulty of replacing what you are used to with with a new gadget.

However, using a new knit technology makes it possible to almost invisible to seamless.That is, instead of hiding the gadget -like part, it creates a gadget from the thread stage.The sensor is completely integrated with the clothes, not the sensor is hidden in the clothes or pasted.

For example, in the technique of the video below, a small patch is created using a conductive material thread that passes electricity, and the patch is applied to non -conductive materials.If you pull or step on this patch, the distance between the conduction materials will approach each other, which will increase the capacity of the electrostatic, so if you measure it with a chip, it will be a pressure sensor.If this patch is incorporated into the socks, you may be able to measure the stride and foot of the runner and prevent the elderly fall.

This technology can also be applied to sensors such as expansion and contraction, temperature, humidity, and more to analyze the amount of sweat (like a lie founder) and estimate the stress level.These applications are actually under development for consumers.Ultimately, the 3D knit structure can be countless sensors, actuators and antennas, and you may be able to make buttons for operation and gesture detection with knit.

One of the biggest issues in the development of these smart fabrics was to make clothes that can be washed many times in the washing machine.In many cases, the solution is called "PUCK" in the industry, which aggregates device batteries and computer parts.Light, vibration motors, and sensors are stored in plastic and laminate tapes for waterproofing, or it is a conductive fiber that can withstand the washing process itself.

Companies like Sensoria are already selling clothes stuck by smart sensors.But in the near future, it will be possible to create smart clothes from the beginning with a single machine, rather than retrofitting smart parts.If you do so, the cost will be reduced and the design will be neat, and you will hardly be distinguished from ordinary knit products.

Gadget is a thread

The evolution of fibers does not simply stop at the level of electricity.I spoke to YOEL FINK, a professor at Massachusetts Institute of Technology (MIT) and a CEO of Advanced Functional Fabrics of America (AFFOA).AFFOA is a US government -owned fabric research center in Cambridge, Massachusetts, USA, with a capital of $ 300 million (about 33 billion yen) and an annual budget of $ 6 million (about 6.6 billion yen).

Through FaceTime interviews, FINK showed various techniques under development.For example, the battery curf knit uses yarn containing a lithium -ion component to accumulate energy in the fabric.

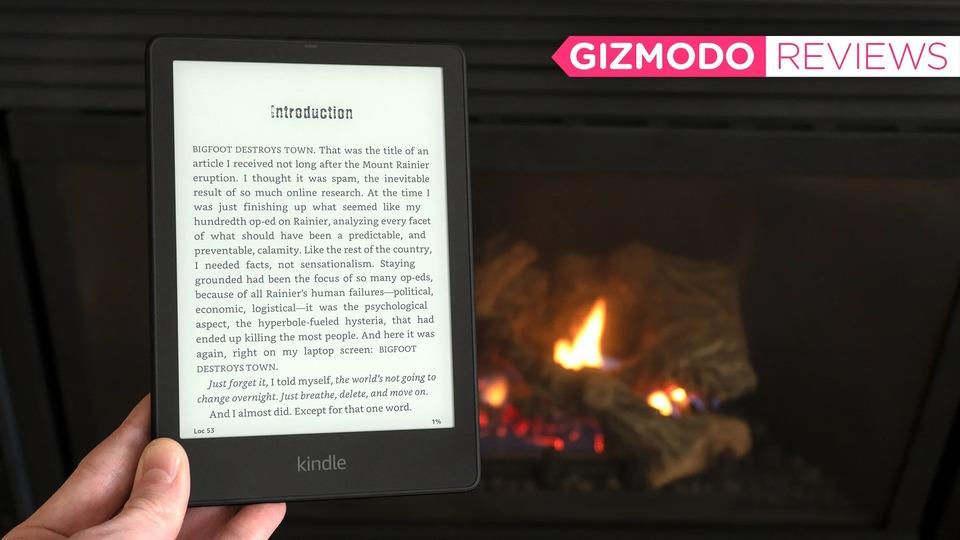

Or a cloth that changes the color with a minimum power (similar to the e-ink display used in Amazon's Kindle), a baseball cap that converts general LED bulb light into sound.Finally, FINK showed me the seemingly normal black yoga pants, but I was able to turn on a small green LED light as needed.

This leggings uses AFFOA's unique technology called "Advanced Yarns".This yarn is made up of a common element with a computer tip such as conduction, insulators, and semiconductors, but to make them "thread", 12 inches (about 30 cm) and about 6 inches (about 15 cm).Heat the tube and stretch it until it becomes very thin.

In the case of this leggings, the thread that is as thin as the hair is knitted to become yoga pants.If you try to make a similar leggings other than this method, you need to manually laminate the LEDs on silicon on your pants, but the comfort is bad, and you need to be careful when handling it.The cost is also high.What FINK has made is hardly distinguished from the general one, but if you turn on the LED, it will help you jogging at night.

When I asked FINK why the knit is suitable for making such smart clothes, the opinion that I heard from Papadopouros mentioned above came back."Knit allows elaborate controls that make use of the potential of clothes. Knit has various levels of freedom in the sense of structure."

In other words, in the case of a knit, it is possible to control the shape of the clothes very detailed, and it is possible to determine where the sensor and actuator are located in the body.This means that it is low cost and can be customized in various ways, and some designers have already made clothes tailored to those who are actually wearing 3D scanning.When you buy smart clothes in the near future, you may have to enter your physical data.

But do you guys wear it?

Both Pailes-Friedman, Papdopolous, and Fink say that smart clothes cost, which will fundamentally change our technologies.And that will change the way people and people and the environment will change.

"We believe it is inseparable from fabrics and humans, so the fabric is perfect for computing platforms, which is one of the disposal we are trying to happen," he developed a smart fabric.According to myant's CEO, Tony Chahine.Fink agrees and predicts that the change will be very fast.

"From now on, the basic nature, performance, and functions of fiber will be improved in the same way as Moore's laws in computer chips," Fink says."According to Moore's law, the functions doubled in 18 months, but I think that fibers will double in a short period of time. The ability of fibers and thread will be improved constantly."

In the end, smart clothes in the future may change our way of thinking about our clothes from the ground up, and may no longer be clothes = things."We don't pay the shirts, but pay for what they can do. We pay for the service and receive the fabric."

"Humans find more value depending on their experiences and services than things," Fink continues."We sympathize with unique things and seek something a little special, and when we get something special, we are willing to pay for it. That's right now.What is happening in the world will see the beginning of a great thing. "

It's been a long time since the age of Egyptian socks.Myant not only protects the feet and blocks the heat, but also develops socks that are squeezing the specified part, measuring posture and stride, and automatically warming up when it is cold.The biggest question in the future is, "What are the consumers want?"Wearable computing creates a huge amount of data about our body, but it is natural that many people feel uneasy.

"How do consumers feel about data?" Pailes-friedman asks."What do they want from the data? Now I think the data is in the middle of love and hate.

While many people prefer things that lead to the Internet, they hear news about hacking, unauthorized use of data, and being deceived by personalized data.I feel that it has gained as much power as many people are anxious.So there are many questions about what data can be done to make people comfortable, what people want people to do. "

It is anxious to think that smart socks will be hacked, but what users want in smart clothes are more basic functions.Pailes-Friedman talked about a jacket that can be warmed or cooled in accordance with changes in the weather.

But what else is the valuable use for ordinary consumers?The people who are now making this kind of technology are focusing on health, safety, exercise performance and rehabilitation.The rest is to warm, cool, shine, and change the pattern.This is all extension of clothes so far, but tech twists come in there.

What functions do you want?

-Gizmodo US [Original] (Miho Fukuda)